EYE PROTECTION SELECTION & CARE

Eye protection is an essential tool in the workplace and while working around home. Why risk losing your precious eyesight when simply wearing eye protection can help safeguard a lifetime of good vision? Experts say proper protective eyewear could prevent up to 90% of all eye injuries.

Safety eyewear must conform to a higher standard of impact resistance than regular eyeglasses. This higher standard applies to both the lenses and the frames of safety glasses and goggles. Normal glasses do not offer sufficient protection in any workplace. In fact, workers using the wrong eye protection have been identified to incur injuries just as much as those who are not using any protection at all.

When you evaluate the hazards in your work area, you must consider the hazards that can harm eyes and select the proper protection.

Eye Hazards

The following hazards pose a threat to your eyes:

- Impact hazards

- Splash hazards

- Optical radiation hazards

Impact hazards are the most common kinds of eye hazards found in workplaces and even at home. They include explosions and flying particles, among others. Depending on the specific situation, safety glasses with side shields or goggles will be the choice here.

Splash hazards are mostly involved when you’re working with chemicals. A splash hazard can occur from a hot or cold spatter of hazardous chemicals in either liquid, mist or powder form. Goggles are the appropriate type of eye protection for splash hazards. They are capable of indirect ventilation that allows air flow without letting powder or liquid spray to get into your eyes.

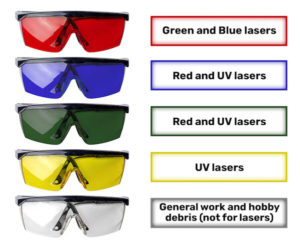

Optical radiation hazards are caused mostly by UV, infrared and visible radiation. Overexposure to any of these elements can lead to eye problems. If you work in conditions where there are optical radiations, you can select specific filter-eye-protection lenses that prevent an optical radiation encounter for the element you are exposed to. In most cases, UV-blocking glasses will work, but if there are high levels of hazardous radiation it may be best to use goggles with filtering lenses.

SELECTING THE RIGHT EYE PROTECTION

SAFETY GLASSES OR GOGGLES

Safety glasses and goggles are forms of protective eyewear that usually enclose or protect the area surrounding the eye to prevent particulates, water or chemicals from striking the eyes. Many projects require employees to wear safety glasses rated ANSI Z87. Eye protection must be used when there is any possibility of substance splash or airborne particles. Safety glasses or goggles are intended to shield the wearer’s eyes from impact hazards, such as flying fragments, objects, large chips and particles. Workers are required to use them with side shields where there is a hazard from flying objects. Non-side-shield glasses are not acceptable eye protection for impact hazards.

Safety glasses

When choosing safety glasses, the primary consideration is to ensure that the glasses provide necessary impact protection and that they meet or exceed the ANSI Z87.1-1989 standard. Both frame and lens must meet this standard to prevent flying and splashing objects from penetrating the lens or entering your eye. Other lenses provide protection by being chemical-attach-resistant, abrasion-resistant or offer other types of protection.

Nonprescription safety eyewear with nonremovable lenses must be permanently marked with the manufacturer’s trademark and Z87 (basic impact) or Z87+ (high impact) on either the front of the frame or on one temple. Prescription safety eyeglasses must be permanently marked with the manufacturer’s trademark and Z87-2 on the front of the frame and on both temples. Whether you are opting for nonprescription or prescription eye protection, be sure to pick those that offer side protection. You should also pick eye protection that fits you well and comes with the appropriate lens coating.

Safety goggles

Goggles are the appropriate type of eye protection for splash hazards, airborne dust and flying debris, such as metal grinding. These situations have a higher chance of a foreign object getting into your eyes from the side. Safety goggles form a complete, form-fitting facial seal to protect you from these hazards. If you are working for long hours while wearing goggles, choose the most comfortable option.

FACE SHIELD

A face shield is a device used to protect the wearer’s entire face (or most of it) from impact hazards, such as flying objects and road debris, chemical splashes or potentially infectious fluids.

However, when worn alone face shields do not protect employees from impact hazards coming from all angles. For additional protection, use face shields in combination with safety glasses or goggles, even in the absence of dust or potential splashes.

CUTTING AND WELDING EYE PROTECTORS

For all types of electric arc processes, a welding helmet complying with ANSI Z87.1, equipped with the correct shade filter, is required to ensure proper vision protection.

EYE STATIONS

As much as you adhere to best eye protection methods, you cannot eliminate the need for an eyewash station(s) in the workplace located in close proximity to where it may be needed. The station is vital in case the eyes come in contact with chemicals and an eye wash is needed quickly, before getting first aid.

CARING FOR AND CLEANING EYE PROTECTION

Like any tool or piece of equipment, eye PPE must be cared for correctly or it won’t be most effective. Knowing how to clean your safety eyewear is essential for its longevity and effectiveness.

Establish a routine to care for safety glasses by using the following quick tips.

- Clean daily. Cleaning can be as simple as rinsing glasses under cool water to remove debris and then drying with a soft cloth. Spraying with a can of compressed air can remove dust and other particles that may have accumulated. Keep a cleaning cloth specially made for glasses handy.

- Use lens cleaner. While water can be an easy way to clean safety glasses, lens cleaners can remove residue that water cannot. Never use soap, which can leave a residue on glasses.

- Clean sides and earpieces too. Sides and earpieces can collect grime, which then migrates onto the lenses, so clean these parts often.

- Avoid abrasive cleaners or rough cloths. These can scratch lenses and make glasses unwearable.

- Avoid household cleaners. Glass cleaners and cleaners used to clean hard surfaces such as countertops can damage any special coating on safety eyewear.

After they’re clean

After your safety eyewear is clean, consider these additional tips for making sure eyes stay protected.

- Inspect daily. Look for any broken pieces or cracks. Even a small crack can cause eyewear to fail to provide adequate protection in case of an accident.

- Consider storage. The best option for storing glasses is in a hard case or microfiber pouch especially made for safety eyewear. Using a microfiber pouch in addition to a hard case is a great option because it doubles as a cleaning cloth for lenses and provides safe storage.

- Use a retention strap or neck cord. Some jobs allow for glasses to be removed at periodic times (e.g., lunch, break time, during a meeting, etc.). Avoid placing them on a workbench or the top of your head, since this puts glasses out of reach when needed again and increases their chances of getting damaged. An eyewear retainer or neck cord allows glasses to hang from the wearer’s neck and keeps them readily available.

- Replace eyewear when necessary. Damaged or scratched safety glasses pose a safety hazard and need to be replaced. Scratched lenses impair vision and strain eyes.

- Use antifog solutions. Many glasses come with antifog technology, but some do not. An antifog solution can be purchased and provide an effective way to keep safety glasses clear of fog.

The above habits are easily implemented in the workplace by providing a readily available and well-stocked cleaning station. Individuals can implement their own system using a personal cleaning kit.

Safety glasses provide much-needed protection for eyes in the workplace and at home. Proper care keeps them effective in protecting your eyes.

Report an Injury

Report an Injury Get Coverage

Get Coverage Manage Policy

Manage Policy Pay Bill

Pay Bill